Disconnected systems and spreadsheets are quietly killing operational efficiency in engineering and manufacturing organizations. When every department—maintenance, quality, engineering, compliance, project management—uses different tools, teams spend more time managing data than improving outcomes.

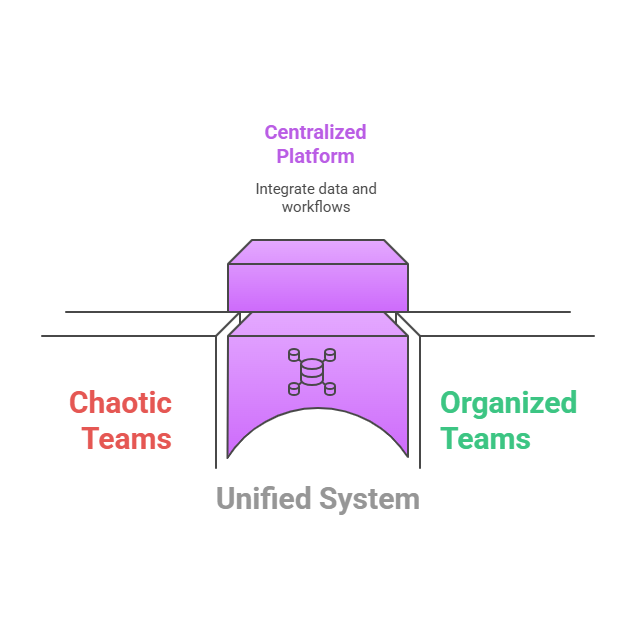

The solution isn’t just better software. It’s one shared platform where all critical functions align around the same truth, the same processes, and the same goals.

Here’s why a unified system isn’t a luxury anymore—it’s a necessity for companies that want to compete, grow, and stay compliant.

1. Disconnected Systems Waste Time and Hide Problems

When assets are tracked in spreadsheets, quality incidents in SharePoint, projects in inboxes, and compliance checklists on paper, it becomes nearly impossible to:

- Make timely, informed decisions

- Spot cross-functional issues early

- Maintain reliable audit trails

Every disconnected tool is a potential failure point.

Before KMD: Hours wasted syncing data across spreadsheets and siloed systems.

After KMD: One platform, real-time updates, and one version of the truth.

2. Shared Enterprise Data Powers Smarter, Faster Decisions

Imagine asset failures, nonconformances, corrective actions, and projects all connected automatically—no emailing updates, no manual data entry.

With shared enterprise data:

- Quality, maintenance, engineering, and compliance teams see the full picture.

- Issues are flagged earlier and fixed faster.

- KPIs are updated automatically from real work, not manual inputs.

Before KMD: Critical decisions made on stale or partial data.

After KMD: Every decision backed by live, complete operational context.

3. End Manual Reporting and Trust Your Metrics Again

In disconnected environments, reporting often means copying, pasting, and praying that nothing changed since the last export.

With a unified system:

- Dashboards pull live KPIs automatically

- Reports update in real time

- Leaders trust the numbers—and act faster

Before KMD: Reporting delays, inaccuracies, and last-minute scrambling.

After KMD: Instant visibility into operational health at every level.

4. Compliance Becomes a Byproduct of Good Process

Managing audits for NADCAP, AS9100, ISO, and ITAR shouldn’t mean assembling artifacts at the last minute. A unified system embeds compliance into everyday workflows:

- Procedures link directly to tasks and outcomes

- Training, calibration, and quality actions are tied to assets and people

- Audit trails are automatic—no hunting, no guessing

Before KMD: Compliance readiness only in panic mode.

After KMD: Compliance built into the process—audit-ready, always.

5. Connect Projects, Preventative Maintenance, and Continuous Improvement

Why manage engineering projects in one system, preventative maintenance in another, and nonconformance investigations in a third?

Everything is connected. Your system should be too.

With KMDProjects:

- Projects trigger updates to maintenance schedules and compliance records

- Asset histories connect directly to quality actions and audits

- Continuous improvement work is documented across functions, not hidden in department silos

Before KMD: Fragmented data, fragmented efforts.

After KMD: Integrated processes that feed each other for faster results.

6. One Platform. One Truth. One Smarter Operation.

When every function operates from the same system:

- Execution is faster

- Reporting is cleaner

- Decisions are smarter

- Teams trust the process—and each other

This isn’t just about software. It’s about building a foundation for scalable, sustainable excellence in engineering and manufacturing operations.

Before KMD: 6 systems, 10 spreadsheets, dozens of conflicting answers.

After KMD: 1 platform, 1 process, 1 source of truth.

Ready to Simplify and Scale Your Operations?

At KMD Technology Solutions, we help engineering and manufacturing teams unify their workflows, automate their processes, and build reliable operations with KMDProjects.

✅ Manage assets, maintenance, quality, projects, compliance, and reporting in one place

✅ Share real-time enterprise data across functions

✅ Drive measurable improvements in efficiency, compliance, and decision-making

Ready to stop managing chaos and start managing success?

👉 Request a demo of KMDProjects today and see how we can help you build the operational foundation your future growth deserves.

#ManufacturingExcellence #UnifiedPlatform #OperationalEfficiency #ComplianceManagement #ProcessAutomation #EngineeringWorkflow #DataIntegrity #ContinuousImprovement #KMDTechnologySolutions #KMDProjects