For many aerospace and defense manufacturers, the word audit still brings tension.

Late nights collecting documents.

Rushed emails.

Missed signatures.

And that uneasy silence in the room when the auditor asks for a record you cannot immediately find.

But it does not have to be that way.

When your processes are mapped, your systems connected, and your data structured, audits stop being events that happen to you, they become milestones that prove your organization is in control.

At KMD Technology Solutions and AIBI, we have spent more than 15 years helping regulated manufacturers move from reactive compliance to proactive confidence.

The results are visible not only in the numbers, but in the people.

Less fear.

More focus.

Better margins.

Here is how it happens.

1. Global Trade Compliance: From Scrambling to Structure

Trade compliance is not just paperwork. It is accountability.

When TAA and export licenses live in inboxes or shared drives, risk grows silently.

The transformation begins when every project is linked to its authorization automatically.

Each document, drawing, and communication is tied to its license record, creating full traceability.

Result: Auditors see control. Teams feel relief.

And what used to take hours of searching becomes seconds of verification.

2. AS9100: From Procedures to Proof

Most companies have the right processes.

Their problem is proving that those processes are followed.

Mapping AS9100 procedures into connected workflows turns compliance from static documentation into living evidence.

Every step, signature, and record becomes part of the story your system tells automatically.

Result: No more binders, no more guessing. Auditors see proof. Teams see progress.

3. NADCAP: From Chaos to Control

Special process audits like heat treat, coatings, and NDT test both your systems and your patience.

When calibration logs, training records, and travelers live in different silos, every audit feels like a rescue mission.

A connected system changes that.

Training logs, calibration data, and controlled documents become instantly available tied to the correct part, operator, and job.

Result: NADCAP stops being a disruption. It becomes a demonstration.

4. Customer Audits: From Panic to Confidence

Customer audits can arrive with little notice.

That is when structure truly matters.

Automated training matrices, controlled work instructions, and instant version visibility make the difference between panic and pride.

When an auditor asks for a qualification, you do not search, you show.

Result: Customers see consistency. Your team feels trust.

5. Traceability: From Weeks of Work to One Click

If it takes a week to prove traceability, the system is working too hard.

Digital travelers, linked NCRs, and integrated certificates turn traceability into a living record.

As work happens, proof builds automatically.

Result: Instead of assembling data, you analyze it.

That saves days of effort and thousands in rework, while improving first-pass yield and audit readiness.

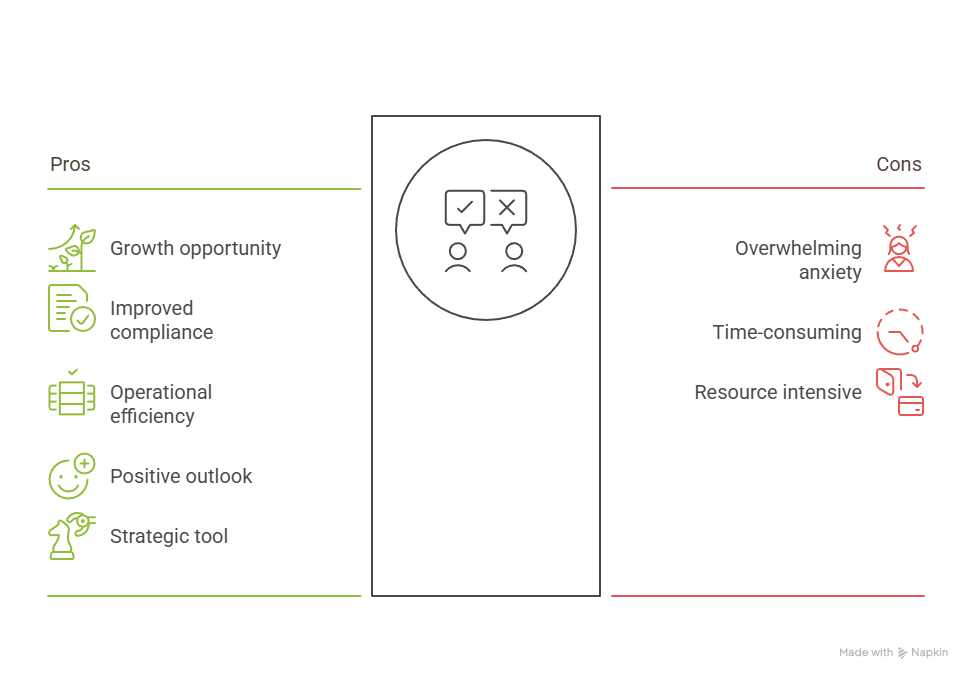

6. From Compliance Burden to Business Advantage

Compliance was once seen as overhead.

Now it is becoming the engine of operational excellence.

When quality, compliance, and operations run on one connected platform, every action creates both evidence and insight.

Leadership gains real-time visibility into risk, readiness, and ROI.

On-prem AI can summarize audit readiness, flag process drift, and produce reports before anyone asks.

Result: The organization grows stronger.

Audits become calmer.

Margins improve.

And people finally have time to focus on what they do best.

The Transformation

Before KMD:

• Teams lose days to audit prep and manual data hunts.

• Stress builds before every inspection.

• Findings repeat because lessons stay buried.

After KMD:

• Every process is mapped and measurable.

• Audit trails build themselves automatically.

• Visibility replaces panic.

• People feel proud, not pressured.

• Compliance drives profitability, not cost.

When structure meets visibility, compliance becomes a culture, not a chore.

The Final Takeaway

Audits will never disappear.

But the fear can.

When your people feel confident and your systems stay aligned, compliance stops being a deadline and becomes a differentiator.

That is how companies reduce findings, improve yield, and increase profitability, all while creating a calmer, more focused workplace.

At KMD Technology Solutions, powered by AIBI, we help aerospace and defense manufacturers turn compliance into confidence with secure, on-prem software that makes quality measurable, traceability automatic, and audits predictable.

📈 Ready to make your next audit the easiest one yet?

👉 Schedule a demo and see how KMDProjects and AIBI can help your team move from pressure to performance.